- Search Database

-

News

- Sweden’s largest nanosafety research programme – Mistra Environmental Nanosafety – launches phase two

- 2020

- Big buzz on nanomaterials in France, 50% threshold with regard to nanomaterial definition criticized

- Nano Silver Used in Face Masks

- Nanoparticle-delivered COVID-19 vaccine candidate

- Nanotechnology-derived graphene used in face masks

- Nano-silver is no longer approved under the Biocidal Products Regulation (BPR) for specific uses

- Titanium dioxide: E171 no longer considered safe when used as a food additive

- New definition of the term ’nanomaterial’ out for stakeholder consultation

- More safety data needed on copper nanomaterials in cosmetics!

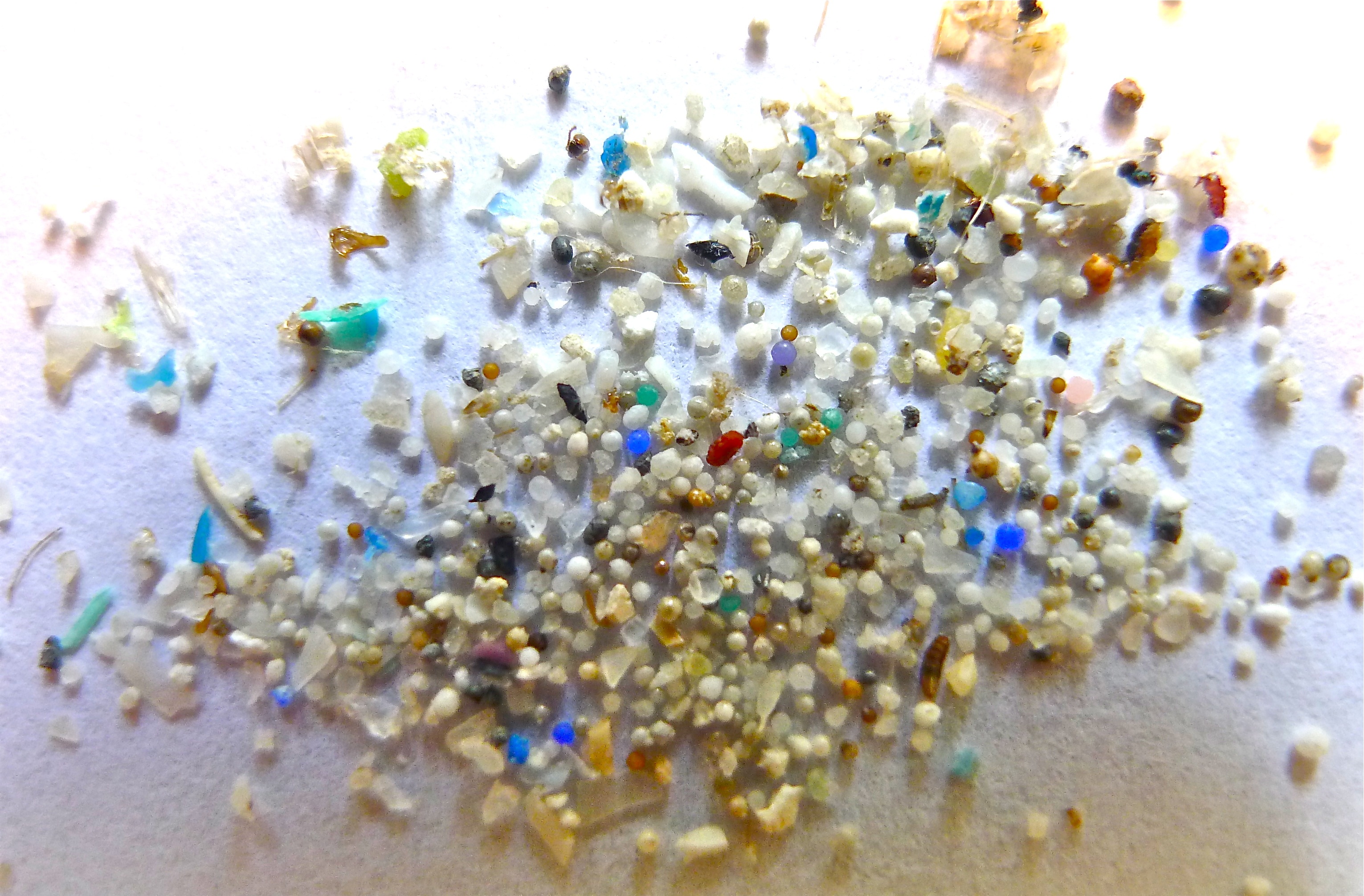

- Nanoplastics found within disposable face masks

- CEFIC assessing impact of EU chemicals strategy on members – biggest project ever conducted by the branch organization

- Annual status report from the Commission on the use of nanomaterials released

- Core elements of the new nanomaterial definition are questioned in stakeholder consultation

- The use of Titanium Dioxide (E171) will be banned in 2022 by EU

- Initial finding in a study on the presence of titanium dioxide in face masks is presented

- ECHA may have overestimated number of substances with nanoform on the EU market - low number of REACH nano registrations bother ECHA, blames industry

- OECD evaluation of 32 nanomaterials exposure assessment tools

- REACH committee to debate restriction proposal on microplastics excludes nanoparticles

- Unlabeled nano substances found in 20 out of 23 substances sold in the French market

- Analysis

- NanoRiskCat

- Report Product

- About us

Page Not Found

- Home

- 404 Page

English

English Danish

Danish